Custom Design

Built especially to fit your space

Fantastic Service

Exceptional service & quality

Dedicated Support

Experienced engineering team

Quality Assured

ISO 9001 quality assurance

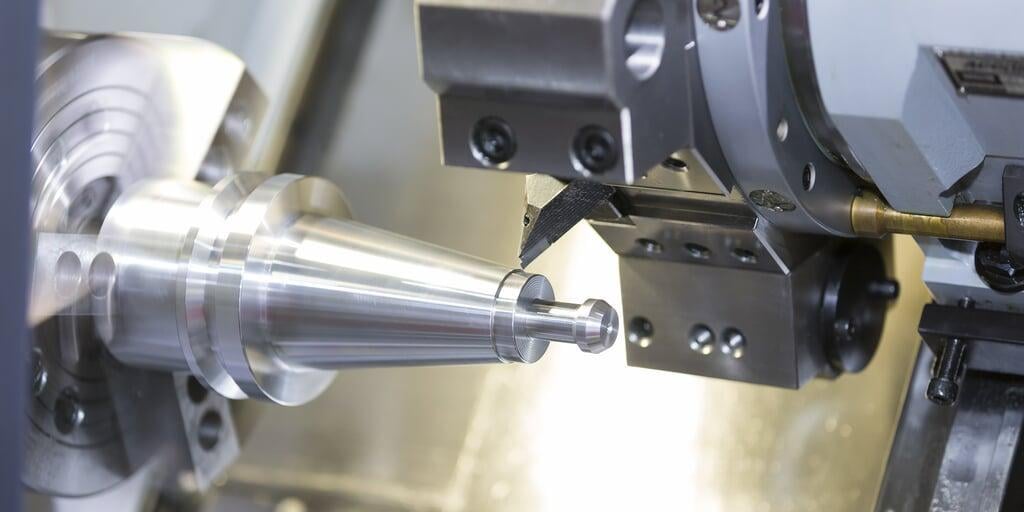

Metal Fabrication Services

Shaw Metal Solutions are expert sheet metal fabricators covering various applications, from simple enclosures and brackets to fully finished sub-assemblies. Our in-house design services are all backed by the ISO9001 quality assurance.

Metal fabrication creates metal structures, components, and products through various techniques such as cutting, bending, welding, and assembling. It involves transforming raw metal materials into finished products ranging from simple components like brackets or frames to complex structures like machinery.

Why Choose Shaw Metal?

We’ve partnered with hundreds of customers, supplying metal solutions to various applications. Solving problems and helping to achieve optimum solutions on time and budget. All are backed by ISO 9001 quality assurance.

Our dedicated design and engineering team are here to help. Providing design suggestions on new product concepts and advising on improvements to achieve optimum volume manufacturing. We support 3D CAD design but are happy to work with simple sketches.

If you are frustrated with your existing supplier or need a fresh outlook to solve a manufacturing challenge, talk to us today.