Built especially to fit your space

Exceptional service & quality

Experienced engineering team

ISO 9001 quality assurance

We have the latest Trumpf True Bend technology for fast, highly accurate folding and bending components up to three meters long.

We’ve invested in the latest Nisshinbo CNC punching technology. We can produce the most intricate formed features and patterns with high-speed precision. Perfect for customised metal components requiring perforated holes, electrical knock-outs, louvres, embossments, part numbers stamps and countersunk holes.

We also have rolling rib and joggle tools that are CNC-controlled and driven around the sheet metal to create seamless forms/stiffeners within the punching operation.

Welding is an essential element in metal fabrication; we have a fully equipped welding shop staffed by highly experienced welders who can support MIG, TIG, Stud and Spot welding requirements.

We have a strong heritage in hand and CNC metal spinning, and in combination with our extensive fabrication equipment, it gives us a unique offering for fabrications requiring spun components.

We have metal rolling facilities to form central canisters, hoppers and cylinder sections.

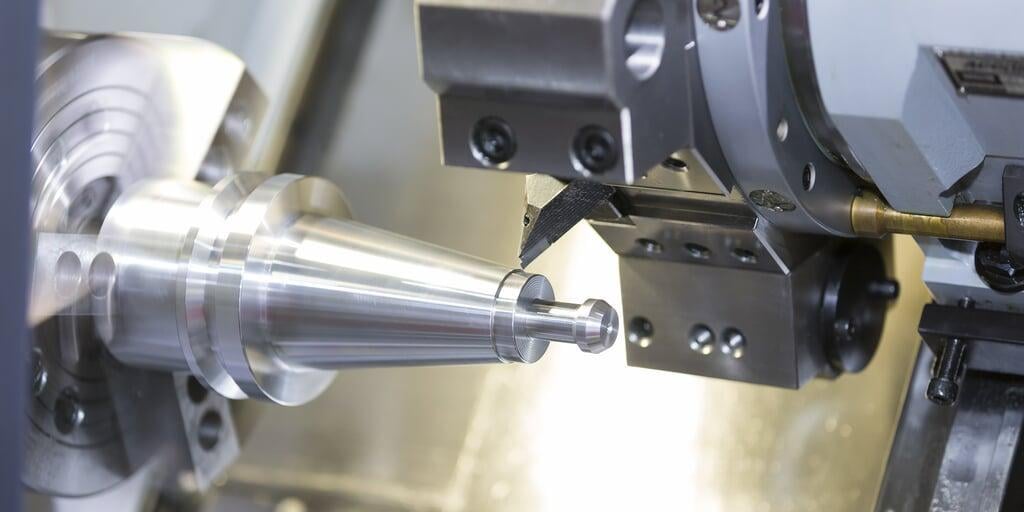

We can produce CNC-turned components up to 700mm in diameter and have our own tools to support our metal spinning operations.

We can offer a full assembly service to produce completed subassemblies or fully assembled products, reducing supply chain complexity and saving time and money.

To complete our turnkey metal fabrications, we can offer a wide range of metal finishing options, including powder coat painting, polishing, galvanising and other speciality treatments.